innovation filter system Pvt. LTD

Everything has to be perfect when you're a manufacturer.

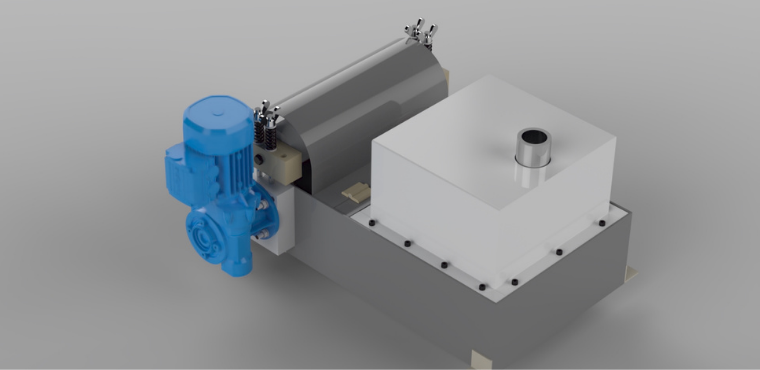

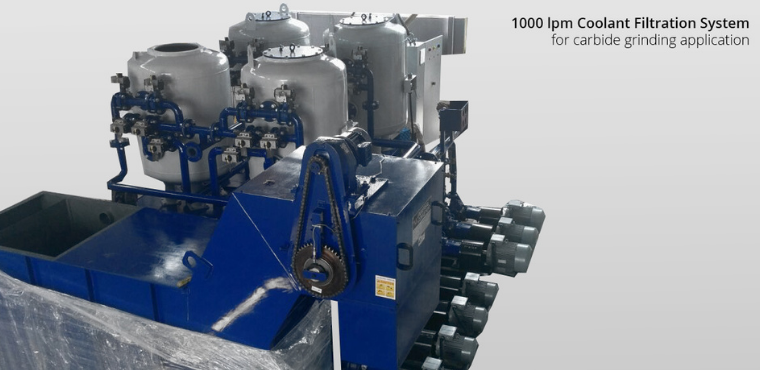

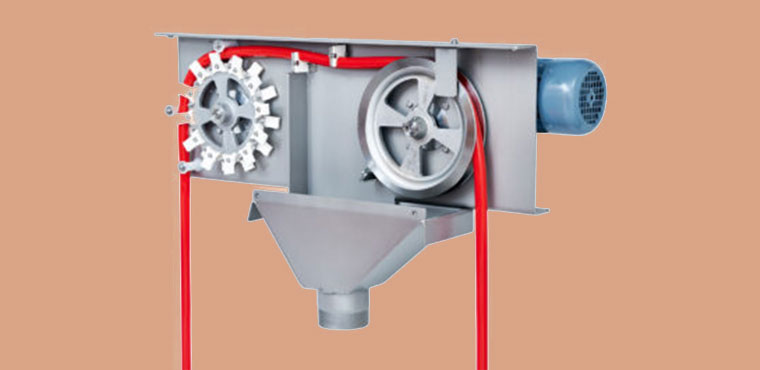

It's not enough to have a good machine tool—you also need suitable peripheral systems. The proper coolant filtration system. The right tramp oil separation system. The right neat cutting oil filtration system & the suitable chip conveyors.

But how do you know what kind of system will work best for your needs? How do you know whether it'll be worth the investment? And how do you know if it'll deliver the results you want?

Contact Us to get these answers.

At Innovation Filter System, we've been helping manufacturers find answers to these questions for over 20 years. We work with some of the biggest names in machine tools, so we know what works—and, more importantly, what doesn't.

Learn more about this filtration system manufacturer in India and its journey.

We specialize in designing systems that ensure your machine tools run at their peak performance. And because we focus on working with small businesses like yours, we can keep costs low while still providing quality service that makes a big difference.

Products

Why Innovation Filter System stands out

We understand that maintaining a filtration system is not your primary business. That's why when engineers at Innovation Filter System sit down to solve your problem, we don't just think about how to make your filtration system work better—we think about how to make your entire process work better.

We know that the filtration system is a part of your cost per component. We also know that prices are associated when implementing and maintaining a filtration system.

Hence, we're committed to offering more value than what we charge while keeping costs low enough so you can stay competitive in your industry.

Filtration systems with value-added service

When we say "value-added," we mean it: Innovation Filter System doesn't just sell filters and filtration systems—we provide value-added services like -

- A free consultation

- Customized designs based on your needs and budget requirements

- Quick turnaround times when it comes to servicing

Because no matter what happens, we made the system and will always be there to keep it running.

Related Articles

References

Customer Reviews

Badve Engineering Pvt. Ltd.

We certify that Innovation Filter system has designed and installed a centrifuge system in our factory, improving our paint process.

Since installation we have realized the following benefits:

- We avoid the manual cleaning of phosphate baths completely.

- We avoid loss due to production shutdown for phosphate tank cleaning.

- Consumption of phosphate bath has come down by 40%

Eagleburgmann India Pvt. Ltd.

Upon installation of IFSs Centralized Coolant filtration system for silicon carbide grinding we were able to save 2400L of water and 120L of coolant along with zero machine downtime for coolant change and bearing replacement.

JS Auto Cast Foundry India Pvt. Ltd.

We are satisfied with the product performance of Tramp Oil separator provided by Innovation Filter System. The sump life and coolant oil quality has increased after using the said product.

KSB Pumps Ltd.

This is to certify that Innovation Filter System has installed a Mineral Bed Filter for our Cylindrical Grinding machine application. Following the installation we have achieved consistency in surface finish, extension of grinding wheel life and zero machine downtime.

.png)