Compact band filter

Filtration system for CNC coolant

Compact band filter systems are most popularly used for coolant filtration applications. Compact paper band filter systems offer better coolant filtration and efficiency than paper band filters because of their design. We offer a very high degree of reliability and guarantees that the coolant will be filtered with the least use of filter paper and motor power.

Compact band filter systems are preferred over paper band filter systems for the following reasons-

- Available shop-floor space is limited.

- As a centralized coolant filtration for a group of machines

- Clean coolant/fluid flow rate is more than 100 lpm (lit/min)

Working of compact paper band filter system-

- In a compact band filter system, the filter paper is held between a pair of sealing discs & a support belt.

- Dirty coolant/fluid flows in the trough formed with filter paper at the bottom.

- The coolant/fluid passes through the filter paper leaving the dirt on it.

- The layer of dirt gathered on the filter paper achieves finer filtration.

- The entire filter is mounted directly on top of the tank, letting clean fluid in the tank.

- As the filter paper chokes, the coolant/fluid level above the filter paper rises.

- This activates a level switch, which drives the support belt.

- This conveys dirty filter paper & dirt to the bin, pulling in clean filter paper from the filter paper roll.

Salient features of compact paper band filter system-

- Filter media consumption is optimized; thus, paper lasts longer.

- The system can be used for water-based emulsion coolant or neat cutting oil filtration.

- The material of construction can be mild steel or stainless steel (SS 304)

- These systems can be used to filter ferrous as well as non-ferrous dirt particles.

- Filtration efficiency between 10-30 microns can be achieved.

Range of Application:

References

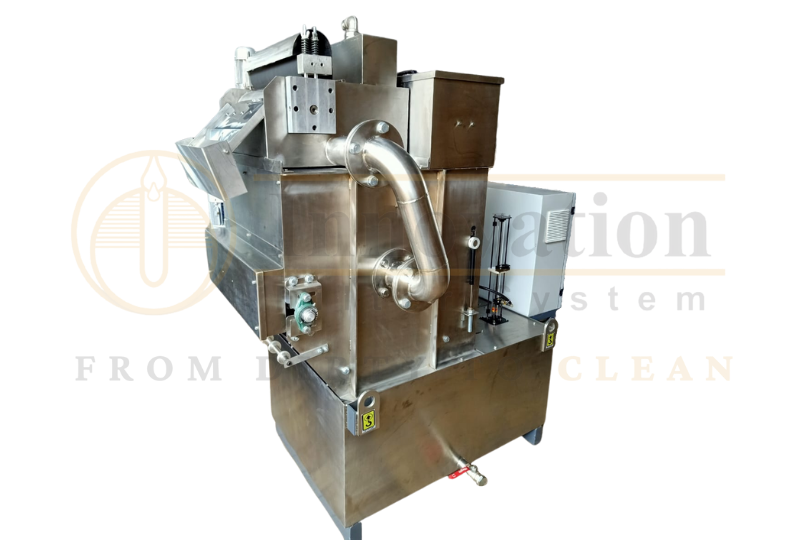

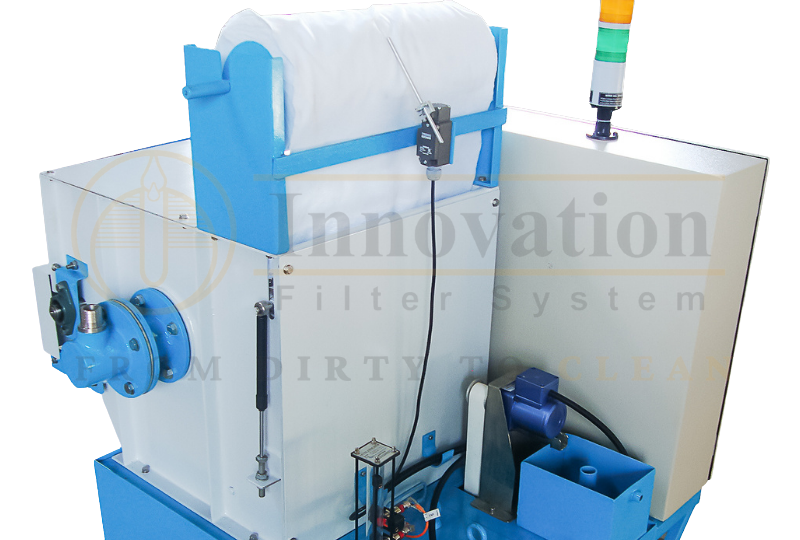

Product Photos