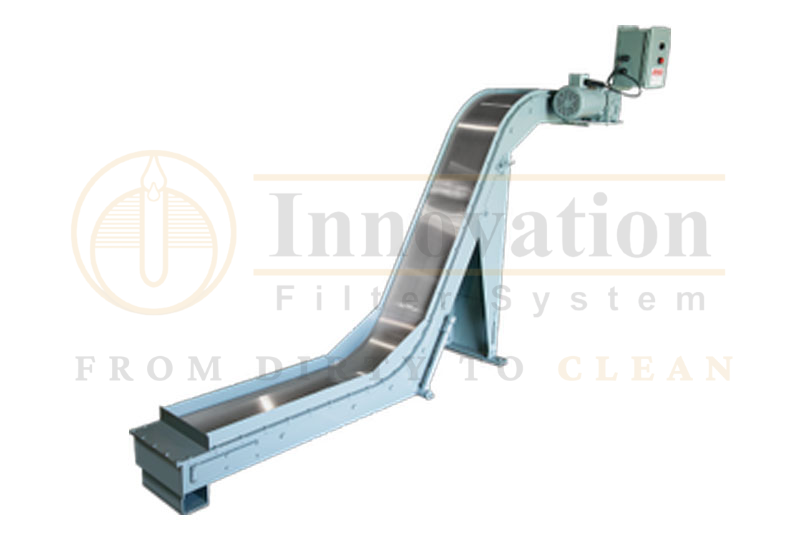

CNC conveyor

Chip removal during CNC machining process

Our design philosophy behind designing our CNC machine conveyors is that machinists should concentrate on making chips and not cleaning them. Our chip conveyors automatically remove chips from your machine and discharge them at the height of a standard industrial barrel.

Our chip conveyors are used for removing chips from machining steel, stainless steel, aluminum, cast iron, and other metals or plastics. We manufacture chip conveyors for CNC lathes, CNC milling machines, machining centers, and other CNC or standard machine tools.

Salient features-

- We design customized chip conveyors for any type of CNC machine like Makino, Haas, Okuma, Mazak.

- The conveyor operation is interfaced with the machine to operate from the machine control panel. The conveyor can be activated used M-codes from the machine panel.

- All our conveyors are based on our unique jam-free operation design.

- For heavy chip loads, the conveyor automatically reverses based on torque overload sensor signals

Product Models

Scraper Conveyor

A scraper conveyor consists of a trough in which a continuous driven chain with scraper blades run throughout the length. The scraper blades scrape the settled debrisfrom the bottom of the conveyor.

Magnetic Conveyor

Magnetic conveyors do not move material using an external belt. Instead, an internal chain of permanent magnets rotates and imparts magnetic force. Underneath, magnets attract the metallic dust, and when in motion, this dust will "drag" across the bed and move to the discharge end.

This design's benefit is that the conveyor can be submerged entirely in material, as its moving parts are shielded from any material that might potentially cause jamming.

Hinged-belt Conveyor

Transportation of the material takes place on the upper trough of a revolving hinged belt. Carriers ensure transport of the material in the inclined section. For wet processing, the coolants are collected in the conveyor housing and fed back into the machine via acoolant tank or a pump station. Our hinged belt conveyors can be used either as stand-alone conveyors at machine tools or as linked conveyor systems.

References