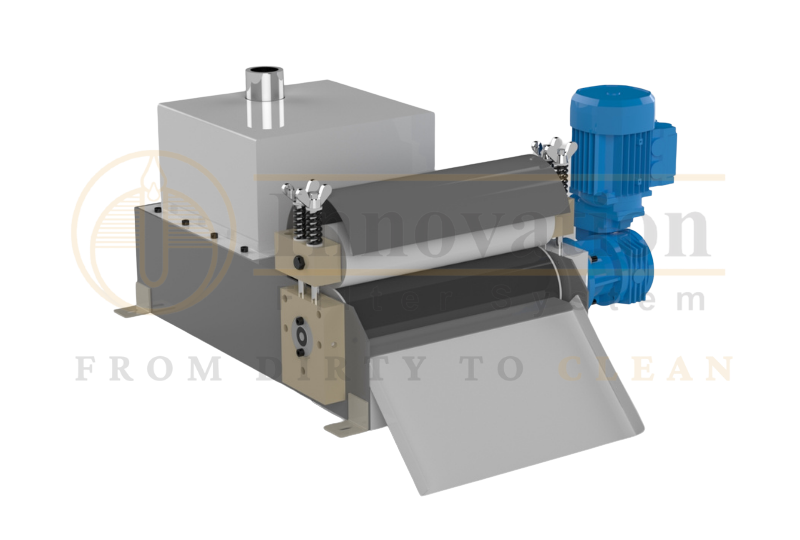

Magnetic coolant separator

Magnetic coolant separator for any cutting fluid

A magnetic coolant separator plays a vital role in your cutting fluid filtration system. These separators are practical, easy-to-use, maintenance-free devices that separate metallic particles from any cutting fluid. In fact, they are part and parcel of almost every fluid filtration system- be it an oil-based or water-based cutting fluid.

Magnetic coolant separator: Designed to perfection

We design our separators for easy installation and maintenance with no piping changes necessary. Moreover, the entering coolant is subject to a powerful, high-intensity magnetic field of close to 4000 Gauss that draws out even the tiniest particles. This unique feature ensures the effective removal of ferrous particles from any cutting fluid.

Most importantly, we have confirmed through various field tests that our magnetic separators can remove metallic particles of less than 50-micron size in a single pass.

The high-strength rare earth magnets used in our magnetic coolant separators are impervious to cutting fluid variation, heat, or vibration. They remove ferromagnetic particles from various fluids, including coolants, honing oil, grinding oil, and wastewater.

Automatic cleaning

A built-in scraping system removes the ferrous particles from the magnet face with each rotation of the magnetic drum. Certainly, auto-scraping maximizes performance and eliminates manual cleaning tasks. A removable cover on the unit allows easy inspection of the separator’s components.

Long-lasting rare earth magnets used in our magnetic coolant separators

The powerful neodymium magnets in our magnetic coolant separators create a high-energy magnetic field. Most importantly, we house the magnets in a non-magnetic stainless steel shell through which the cutting fluid flows. Ferrous fines are attracted to the powerful magnet. On the other hand, nonferrous fines pass through unaffected.

Typical applications for the magnetic coolant separator include machine tools such as surface grinders, cylindrical grinders, and belt grinders. Moreover, our magnetic separators are best suited for grinding, honing, and gear cutting applications.

The low total cost of ownership of our magnetic separators

Our magnetic coolant separator produces dry sludge- free of cutting fluid every single time. Therefore, the separators pay for themselves within six months while reducing maintenance costs by up to 30% compared to traditional methods. Indeed, you don’t have to wait to see cost savings either—you’ll start saving money right away, and the savings will keep building over time.

It’s a no-brainer solution for anyone trying to reduce maintenance costs and save money on their production line.

Try our magnetic coolant separator risk-free- Contact us for a high-performance magnetic coolant separator.

References

Product Photos

.png)

.png)