Classical transor filtration units- TB4

TB4: Trusted by more cutting tool manufacturers around the globe

Transor filtration system's first design was using 'TB4' or what we usually refer to as 'filter candle' or only 'candle.' Before the Transor's TB4, end-users struggled with various forms of filtration, including paper roll filters, cartridges, centrifuges, and pre-coat systems. These provided low filtration levels, high operating costs, and were maintenance intensive.

Transor filtration system's-TB4 design is well known, reliable, and sturdy technology. These systems are recommended for tool and cutter grinding machine users to make a mix of carbide and HSS cutting tools.

Working of Transor- TB4 system-

- The Transor System provides One Micron Filtration and is virtually maintenance-free.

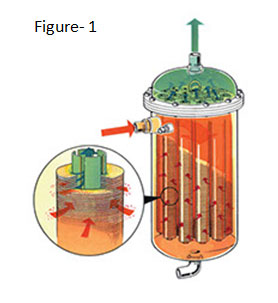

- Transor systems operate on the principle of edge filtration in which dirty oil is forced toward the center of each element, trapping particles larger than One Micron on the filter "edge" (FIGURE 1).

- Rather than being replaced, the elements are cleaned automatically with compressed air that removes the debris and places it into a sludge bag or a scraper conveyor for reclamation or disposal (FIGURE 2).

- The filter elements' life expectancy is approximately 25,000 hours; however, this figure is often greatly exceeded.

References

Product Photos