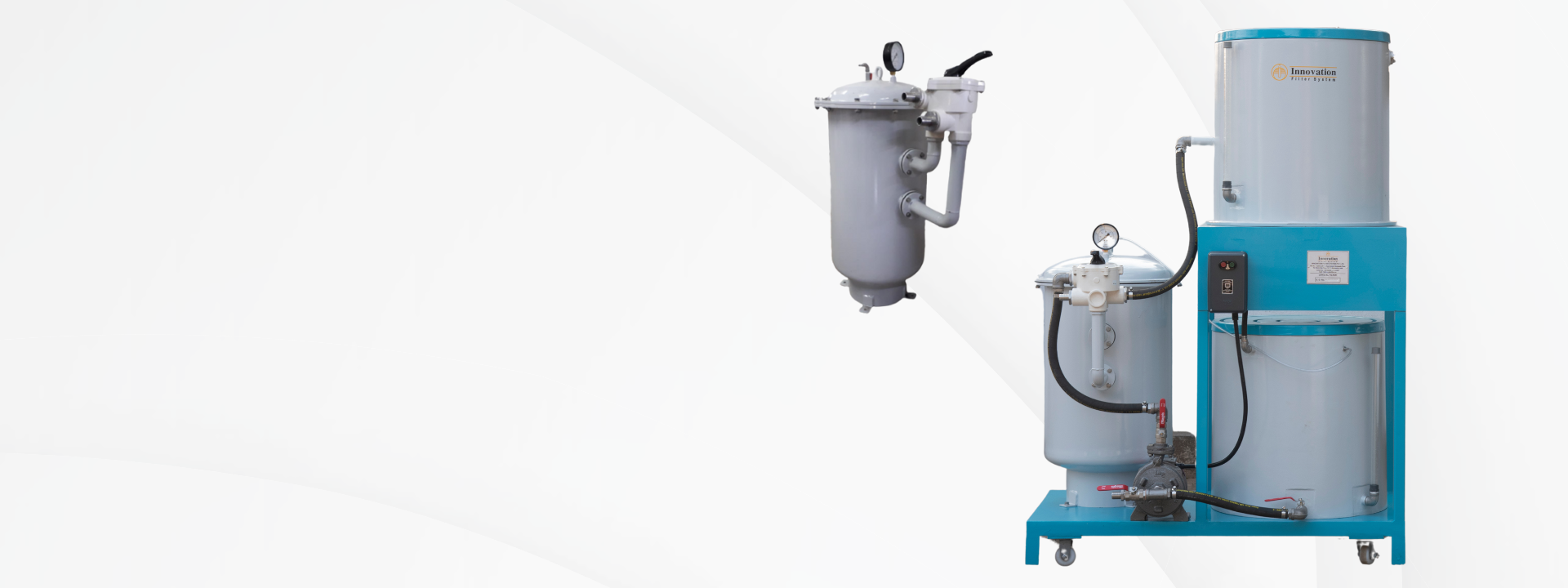

Mineral Bed Filter

Wire cut: MBF- a fantastic filter for your expensive machine

Mineral Bed Filter (MBF) is a semi-automatic filtration system for dielectric fluids used in wire cut machines. It increases the life of your consumable filter cartridges by at least 300%, meaning you can use them for months and months longer.

MBF's powerful filtering system removes contaminants from your dielectric fluid. It keeps it sparkling clean and prevents costly machine damage. Thus, having an MBF directly impacts the performance and efficiency of your wire cut machines, resulting in less downtime and increased production. The MBF achieves this while reducing maintenance costs.

Please click here to understand the importance of clean dielectric fluid (de-ionized water) in wire cut machining.

The problem is that wire cut machines consume a lot of filters.

One of the most common problems manufacturers face with wire cut machines is an excessive need for cartridge filters. This is consistent with the feedback we receive from our customers before the installation of MBF. For example, S.B. Engineers- a die & mold industry veteran, mentioned in their testimonial-

"Since we run our machines 24X7, we had to change the filter cartridges in our wire cut machines every 15 days. However, after installing the MBF system from Innovation Filter System, we change them only twice a year."

Modern, mid-range, and high-end wire cut machines have built-in consumable filters. The problem is that you have to change these filters frequently. Thus, impacting your bottom line. Especially if you're using a more high-end machine, these filter cartridges are costly, especially for imported wire cut machines.

So naturally, some manufacturers try to solve the problem by using cheaper filters in their high-end machines. But this always ends up backfiring on them. It badly affects the quality of the materials being machined. This means manufacturers have to spend even more money on machine repairs or high wire consumption.

MBF: an innovative and eco-friendly solution for profitable wire cut machining

We have been proud of our association with Electronica India and Electronica Hitech for more than 20 years. Our MBF systems equip almost all of their machines.

- Eco-friendly filter medium- We use quartz sand as filter media.

- Zero water wastage- We backwash the sand using water within a closed loop.

- The option of manual and fully automatic systems is available.

- We can provide a retrofit solution for any wire cut machine like Fanuc, Sodick, Agie-Charmilles, Mitsubishi, Makino, Electronica, etc.

If you have wire cut machines, you'll love that the MBF helps you increase your productivity with a low-cost solution.

Contact us to discuss your specific requirements.

Please check our latest article on the topic of wire cut EDM-

References

Product Photos

.png)